|

Structure and properties of WBC, MoBC and TaBC coatings |

||

|

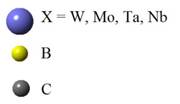

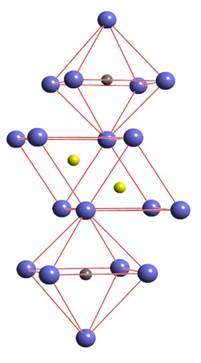

Schematic

view of X2BC structures |

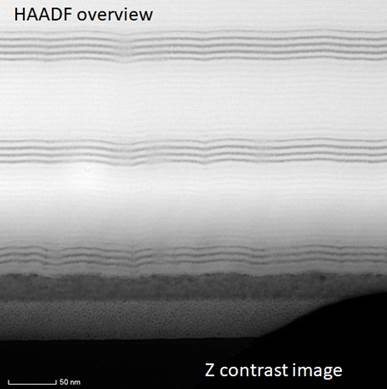

The apparently contradictory properties of high hardness and ductility may be realized in X2BC systems (X = Ti, V, Zr, Nb, Mo, Hf, Ta, W) by an-initio calculations. These compounds are composed of alternating stiff carbidic and boridic layers and metallic interlayers (left), realizing nanostructuring at the atomic level and providing both stiffness and ductility for the films. In this cooperation WBC, MoBC and TaBC films were investigated in cooperation with Masaryk University (Brno) to overcome the general fragility of recently applied ceramic coatings. The coatings were mostly amorphous-polycrystalline nanocomposites wit grain size in the range of 5nm. All the layers exhibited high hardness (>20GPa) so they all can be classified as hard coatings. In a WBC coating deposited in an industrial chamber a hierarchical multilayer structure was revealed (right) which is composed of ~5nm layers. |

STEM-HAADF image of a WBC coating sputtered in an industrial chamber. The hierarchic multilayer structure, composed of ~5nm layers, was formed due to the double rotation mechanism of the sample holder |